Aluminum Corrosion And Its Different Types

Aluminum is the second largest metal on the planet, and due to its excellent properties, it is one of the most widely used metals today. Therefore, it is useful to understand the conditions that shorten the life of these metals.

Aluminum is the second largest metal on the planet, and due to its excellent properties, it is one of the most widely used metals today. Therefore, it is useful to understand the conditions that shorten the life of these metals.

The corrosion of any metal will greatly affect its functional strength, and in extreme cases will lead to structural damage, such as cracks, partial fractures and complete material failure.

What is aluminum corrosion? Aluminum corrosion refers to the gradual decomposition of aluminum molecules into oxides, thereby reducing its physical and chemical properties. In essence, aluminum is an active metal, but it is also a passive metal.

Types of aluminum corrosion

Atmospheric corrosion

The most common form of aluminum corrosion. Exposure of aluminum to natural elements can cause atmospheric corrosion. Since it can occur in most places, atmospheric corrosion constitutes the largest share of the total damage to aluminum caused by all types of corrosion in the world.

Electric corrosion

Galvanic corrosion, also known as dissimilar metal corrosion, affects aluminum physically or through electrolytes connected to precious metals. The noble metal may be any metal with lower reactivity than aluminum.

Pitting

Pitting corrosion is the surface corrosion phenomenon of aluminum metal, which is characterized by small holes (pits) on the surface. Generally, these dimples do not affect the strength of the product. Rather, this is an aesthetic issue, but if the surface appearance is critical, it can lead to failure.

Crevice corrosion

Crevice corrosion is a form of localized corrosion process in materials. Overlapping materials or accidental design errors can lead to the formation of gaps. As a result, collecting seawater in these bags can cause crevice corrosion.

Exfoliation corrosion

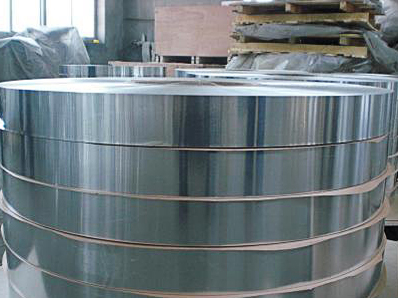

Exfoliation corrosion is a special kind of intergranular corrosion in aluminum alloys, with obvious directional structure. This is particularly obvious in aluminum products that have undergone hot rolling or cold rolling.