How to judge an experienced machining project?

1. Good process ability. When we get a drawing of a mechanical part processing drawing, we must quickly work out the processing technology of this drawing in our mind, from processing equipment, tools, fixtures, checking fixtures to processing costs These steps have the most basic judgments, and these judgments must be accurate judgments based on your professional ability and professional experience. To develop a good process ability, in addition to the knowledge of the processing technology, it is also necessary to have a full understanding of the products assembled by the processed parts, because the processing requirements of a part must be formulated based on the assembly requirements of a product Yes, many young design engineers do not have such comprehensive awareness when doing part design, so a good process engineer must not only define a reasonable part processing technology for the product, but also have the ability and awareness to modify and improve the design engineer’s Deviations are used to optimize the manufacturing process of products from the rationality of part structure design, material selection reliability, alignment tolerance accuracy, and manufacturing cost minimization. In fact, this is the greatest value of mechanical process engineers.

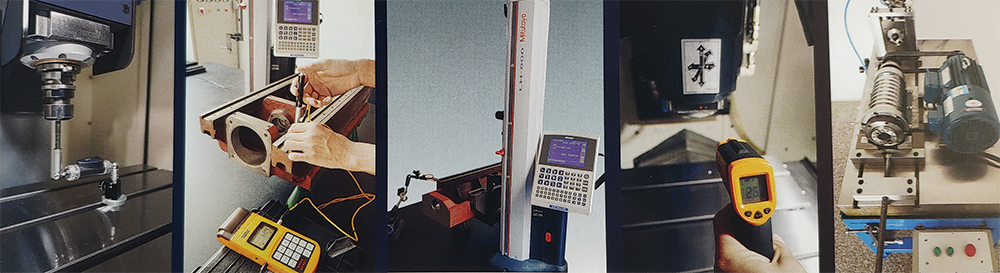

2. Familiar with the processing equipment of your workshop. What I mean by familiarity means that you must be familiar with the processing capabilities and scope of the various processing equipment in your workshop, and what kind of processing accuracy they can achieve.

1) Machining capabilities, what kind of processing equipment does your workshop have? For example, turning, milling, planing, grinding, boring, drilling and other machine tools, what kind of parts processing procedures are they suitable for processing, you can get a drawing Can quickly confirm the processing procedures of this part and what equipment is required to complete these processing procedures, and then compare the existing equipment in your workshop to make a judgment of processing ability. This is a qualified mechanical processing engineer must have At the same time, if there is no corresponding processing equipment to complete the processing of the part, we have to consider whether we can expand the processing range of some existing equipment through special tooling or cutting tools. This is for a good process engineer It is also a very challenging subject. In many cases, as long as we do not give up, there are always more ways to solve the problem than difficult.

2) The processing range, mainly refers to the processing stroke of the processing equipment in your workshop, because although many equipment types are the same, they have specifications and sizes. The processing range of large-scale equipment is naturally larger. When you get it When drawing a drawing, you must quickly determine whether the processing equipment in your workshop is capable of processing according to the outline dimensions of the drawing. Let’s not discuss the accuracy of processing, at least confirm that the processing stroke must cover the size of the part. In fact, as far as the processing range is concerned, we can still achieve the processing of some processed parts that exceed the equipment stroke by one installation, two clamping, and base surface positioning. The key is to be bold in the processing technology of the parts. Innovation and breakthrough.

3) Machining accuracy, you must have a very good understanding of the processing accuracy of the processing equipment in your workshop, what kind of equipment can achieve what processing accuracy, especially according to the requirements of the drawings to achieve the corresponding processing accuracy, this is very Important, otherwise you will not be able to complete the customer’s acceptance of your machining quality. If the machining accuracy of the machine tool has been deviated, the experienced mechanical process engineer can adjust the clamping method of the workpiece by the deviation law of the machining accuracy of the machine tool Step-by-step processing and multiple inspections to achieve effective processing of parts. Of course, this processing method is a last resort under special circumstances. For equipment with precision deviations, it is still necessary

Timely repair and maintenance are king, but a good process engineer must be flexible and eclectic. They will always be the cornerstone and confidence of the parts processing process. The workers in the workshop only need to see him. If you feel dependent, you know that everything is under control.

3. Machining tools, what kind of tools are used for the processing of what materials, what processing speed and feed rate are equipped, whether cooling is needed, and there should be corresponding procedures for rough machining, semi-finishing and finishing. The transformation of tools and processing parameters must not only ensure the processing quality and processing efficiency, but also take into account the processing cost, because this is always a business behavior, and it is unethical to operate without profit, and the choice of tools is very big. Knowledge, because it is closely related to the manufacturing cost of the parts. A good tool can not only improve the processing quality and processing efficiency of the parts, but also effectively ensure the stability and durability of the machine tool. At the same time, it can effectively ensure the cycle of the part production and the Reasonable selection is the basic skill of a process engineer, and it is also a killer skill of a process engineer. To a large extent, this skill is fed with money, because only after a large tool experiment and processing accumulation can one form his own experience, and its cost The height and the length of the cycle are daunting and awe-inspiring.

4. Machining fixtures, according to the shape of parts and machining accuracy requirements, design general or special processing fixtures. Compulsory courses and necessary skills for every mechanical processing engineer. A good fixture can not only improve the processing efficiency of parts, but also greatly The improvement of the machining accuracy of parts can also expand the processing range of machine tools and reduce the cost of parts processing. Especially with the advancement of science and technology, especially the rapid development of electrical control technology, the current tooling fixture has gradually Moving forward in the direction of automation, combined with the design of pneumatic and hydraulic systems, through the use of electrical components, a set of professional automated fixtures has become a standard accessory in the modern machining process, especially for mass-processed products, and a large number of applications that require automated fixtures , This not only greatly improves the efficiency of workers’ clamping, but also greatly reduces the labor intensity of workers, improves the working environment, and enhances operational safety. At the same time, it also has a great guarantee for the quality of parts.

5. Processing inspection tools. In fact, many people think that the completion of the processing of a part means that the work is completed, and the money can be collected and left. In fact, this is a big mistake. Each part and each processing procedure needs to be equipped with the corresponding In this way, the processing quality of the parts can be guaranteed, and a comprehensive quality inspection must be done at the end. According to the size and shape tolerance requirements of the parts, roughness standards, etc., a comprehensive quality evaluation of the parts can be carried out. Only after these processes can it be said that the processing of each part is completed. From the face to ask customers for money, in old state-owned enterprises, each workshop will be equipped with a quality inspection station as standard, and the quality inspection personnel have standards for the quality inspection of the workpieces.

The tooling equipment and operating procedures are more professional and standard inspection documents are used as the circulation certificate of the parts. A good process engineer must have a general understanding and familiarity with the specifications of the quality inspection of the parts, the procedures and inspections, only in this way, Only in this way can we formulate the processing technology of parts and produce qualified products.

6. Control the cost of parts processing. Any mechanical processing that does not count the cost is called hooligans. This behavior is tantamount to killing chickens and getting eggs. It is not something ordinary people can do. A good mechanical processing engineer can not only be perfect To complete the processing of various parts, it can also minimize the cost of the entire processing process, so that it can be regarded as doing the duty of a mechanical processing engineer. Any awesome technology engineer, its greatest value is the processing of parts Many people think that cost control is the grasp of the processing quality of parts. In fact, in today’s market economy, cost and quality have become a double-edged sword for enterprises. If you are not careful, both blades can hurt people. Cost-controllable processing quality is the effective processing quality, otherwise it is really a hooligan.

If you’d like to speak to a member of the Anebon team, please get in touch at info@anebon.com

![]()