Material of The Plastic Prototype

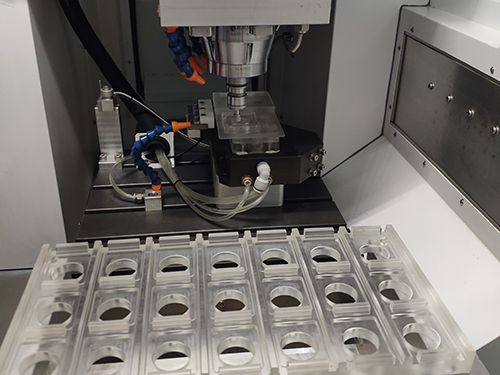

CNC plastic prototypes usually use ABS, PC, nylon, etc. The following are the material properties for reference.

ABS organically combines the properties of PB, PAN and PS. Therefore, ABS has good impact strength, dimensional stability, low water absorption, good corrosion resistance and high mechanical strength. ABS also has excellent chemical properties and electrical insulation properties. It can maintain its shape when heated.

PC (polycarbonate) is a transparent material with excellent properties in terms of mechanical properties, insulation properties and heat aging resistance. It is usually used to manufacture medical prototypes and beauty equipment.

PA (nylon) is an important engineering plastic with excellent toughness and wear resistance. Oil resistance, weather resistance, high temperature resistance and other characteristics are widely used in the automotive industry, including instrument panels, seats, handles, engine covers, electrical sockets and other parts.

POM (polyoxymethylene) has high wear resistance, high mechanical strength and rigidity, but poor corrosion resistance and adhesion.

There are many materials that can be used to make CNC machined plastic prototypes. Materials with different properties can be used to make different functional prototypes. Want to realize your design, welcome to contact us info@anebon.com.