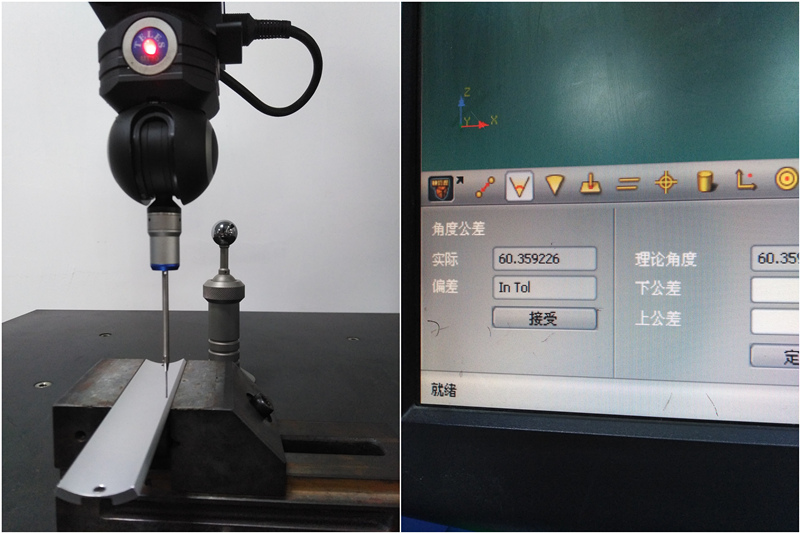

Testing Components By CMM

The measurement principle of CMM is to accurately measure the three-dimensional coordinate values of the surface of the part, and to fit measurement elements such as lines, surfaces, cylinders, balls through a certain algorithm, and obtain the shape, position and other geometric data through mathematical calculations. Obviously, accurately measuring the coordinates of the surface points of the parts is the basis for evaluating geometric errors such as shape and position.

The operation and use of the CMM machine requires a professional knowledge base, and it is difficult for non-professionals to perform post-programming and other operations. More importantly, there is no uniform standard for measurement methods, such as the number of points, the selection of positions, etc. But our testing department has corresponding professional experience and can test most products.

Quality and service are the foundation of our long-term cooperation with customers. So we are never sloppy.